What Do You Need For A Hot Tap?

A hot tap is a procedure used to connect a new pipeline or other component to an existing system without any interruption of service. It is a specialized type of plumbing fitting that allows a valve to be installed in an active pipe so that a branch connection can be made without having to shut down the entire system. To complete a hot tap, you will need a wide variety of specialized tools and materials, such as a drill, a hot tap machine, appropriate piping, fittings, and valves, as well as safety equipment and personnel.

Identifying Your Hot Tap Needs

Hot taps are a great way to quickly and easily add connections to existing pipes and systems. However, before you can start the hot tapping process, you need to identify your hot tap needs. This includes determining the type of tap, size of the tap, and the connection type.

When it comes to the type of tap, there are a few different options to consider. Depending on the material of the pipe, you may need to use a mechanical or a welding tap. In addition, there are different types of taps that vary in size and connection type.

Next, you need to identify the size of the tap. Taps come in a variety of sizes and you need to make sure you choose the right one for your application. You may need to measure the pipe or consult with an expert to determine the correct size.

Finally, the connection type is important to consider as well. Hot taps can be connected directly to the pipe or through a fitting such as a flange or a union. The connection type can also determine the type of tap you need and the size of the tap.

Identifying your hot tap needs is essential for a successful hot tapping project. By understanding the type of tap, size of the tap, and the connection type, you can ensure that you have the right tools and materials for the job.

Understanding Hot Tap Types and Specifications

Hot tapping, also known as pressure tapping, is a process that allows for the installation of a tap into an existing pipeline without interruption of service. It is a useful tool for many industries, from oil and gas to plumbing and water services. To perform a hot tap, the right tools and equipment must be used. In this article, we will discuss what is needed for a hot tap and the different types and specifications that are available.

When it comes to hot tapping, the most important piece of equipment is the tap itself. The type of tap used will depend on the type and size of the pipe or vessel that needs to be tapped. Different types of taps are available for different materials, such as steel, copper, or plastic. It is important to ensure that the tap chosen is suitable for the job at hand.

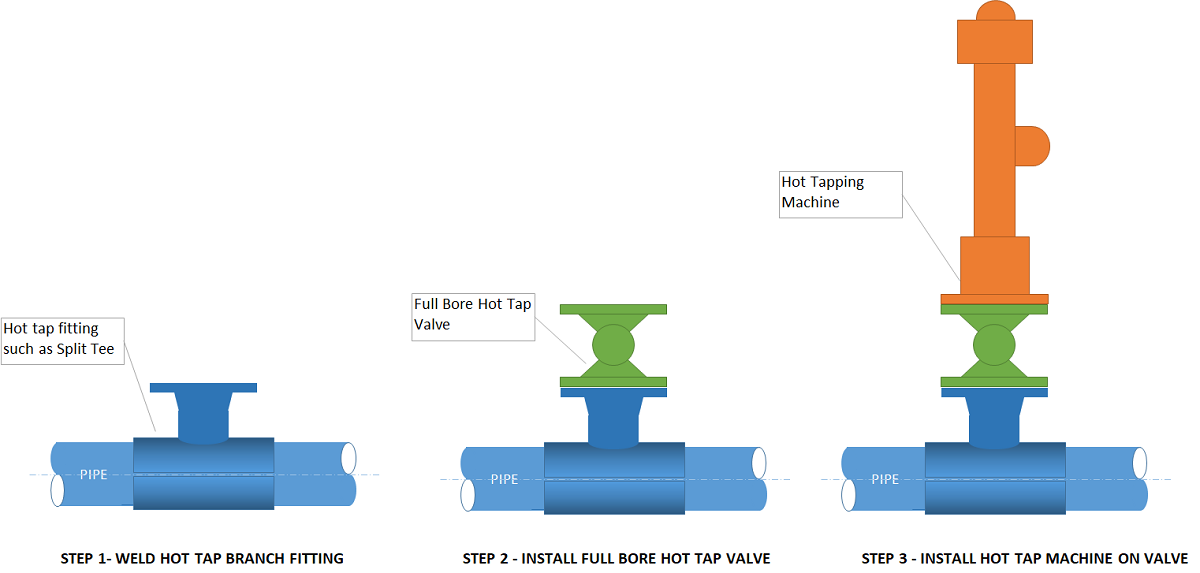

In addition to the tap itself, a hot tapping kit will also contain other necessary items. This will typically include a shut-off valve, a drill, and a tapping machine. The shut-off valve is used to prevent any fluid from flowing through the hot tap. The drill is used to create a hole in the pipe or vessel, while the tapping machine is used to create the threads for the tap. Hot tapping kits are also available that include all the necessary tools and equipment.

Hot tapping can be a difficult process, so it is important to ensure that the right tools and equipment are used. Knowing what is needed for a hot tap will help to ensure that the job is done safely and correctly. By understanding the different types and specifications that are available, it will be easier to choose the right equipment for the job.

Selecting and Installing the Right Hot Tap Fitting

Hot tapping is a process of making a connection to an existing pipe or pipeline without creating a disruption. To do so, you must have the right Hot Tap fitting. Whether you’re looking for a fitting for a commercial, residential, or industrial project, there are some key considerations to make when selecting the right Hot Tap fitting for the job.

When selecting a Hot Tap fitting, the first thing to consider is the type of pipe material you’re connecting to. Different fitting materials may be required, depending on the type of pipe you’re connecting to. You’ll also need to consider the pressure and temperature requirements of your project, as well as the size and shape of the pipe.

Once you’ve selected the right Hot Tap fitting, you can begin the installation process. It’s important to ensure that the fitting is properly installed to ensure that the connection is secure and safe. Depending on the type of fitting you’re using, the installation process may vary, but the general steps are the same. You should start by properly cleaning the pipe and then mounting the fitting, followed by testing and inspecting the connection.

Whether you’re looking to install a new fitting or replace an existing one, selecting and installing the right Hot Tap fitting is key. Taking the time to choose the right fitting and properly install it will ensure that your project is a success.

Understanding Hot Tap Safety Considerations

Hot tapping is a complex process that requires expertise and experience to complete safely. Before you consider this type of repair, it is important to understand the safety considerations associated with hot tapping. While installing a hot tap can be beneficial, it can also be dangerous if not done correctly.

In order to ensure the safety of everyone involved, it is important to take the proper precautions. The most important safety consideration for hot tapping is to have the right safety gear. This includes safety glasses, hard hats, gloves, and steel-toed shoes. It is also important to use the correct tools for the job, such as a hot tap machine and a drill bit.

In addition to having the right safety gear and tools, it is also important to assess the integrity of the pipeline before you begin. This includes performing a pressure test and visual inspection. It is also important to consider any environmental hazards that could be present, such as hazardous gases or liquids.

Finally, when performing a hot tap, it is essential to follow all applicable safety regulations. This includes following the manufacturer’s instructions, adhering to local and state regulations, and working with an experienced professional.

Overall, hot tapping is a complex process that requires expertise and experience to complete safely. It is important to take the proper safety precautions, use the correct tools for the job, assess the integrity of the pipeline, and follow all applicable safety regulations. Taking these precautions can help ensure that the hot tapping process is completed safely and successfully.

Proper Maintenance and Troubleshooting of Hot Tap Fittings

Hot tap fittings are an essential component of any plumbing system. While they may seem simple to install, it is important to ensure that they are maintained properly to prevent problems. Proper maintenance and troubleshooting of hot tap fittings is essential to prevent costly repairs or replacements. This article will discuss the necessary steps to properly maintain and troubleshoot hot tap fittings, as well as provide some tips on how to avoid common problems.

First, it is important to understand the different components of a hot tap fitting. The main components are the body, the handle, the stem, and the seat. It is important to check each component for any signs of wear or damage, as this can lead to leaks and other problems.

Next, it is important to ensure the connections are secure and tight. This includes both the connections between the hot tap and the other plumbing fixtures, as well as the connections between the components of the hot tap itself. If the connections are loose, it can cause air or water leaks.

Finally, it is important to ensure that the hot tap is properly lubricated. This is especially important if the hot tap is used in an area with extreme temperatures. Proper lubrication will help to avoid corrosion and make sure the hot tap can function properly.

By following these steps, you can ensure that your hot tap fittings are properly maintained and troubleshooted. With proper care and maintenance, your hot tap fittings will last for years to come.

Benefits of Hot Taps

Hot tapping is a useful technique for making connections on pipes, tanks, and other vessels while they are still in service. This method can save time and money by avoiding the need to shut down the system for repairs or maintenance. As such, hot tapping is becoming an increasingly popular choice for many industrial applications. There are many benefits associated with hot tapping, including improved safety, reduced downtime, and cost savings.

Safety is a major concern for any industrial process, and hot tapping can provide a much-needed boost in this area. By allowing workers to make connections without having to shut down the system, hot tapping eliminates many of the risks associated with traditional methods. This can protect workers from potentially hazardous conditions and prevent the system from releasing potentially hazardous materials.

Hot tapping can also reduce downtime. By avoiding the need to shut down the system, hot tapping can keep the process running while repairs or maintenance are being performed. This can reduce the amount of time that the system is offline, which can help to keep operations running smoothly and efficiently.

Finally, hot tapping can also provide significant cost savings. By eliminating the need to shut down the system, hot tapping can lower the amount of labor required to make repairs and maintenance. It can also help to reduce the need for additional equipment and materials, which can help to minimize the overall cost of the project.

In conclusion, hot tapping offers many important benefits, including improved safety, reduced downtime, and cost savings. It is becoming an increasingly popular choice for many industrial applications, and it is a great way to make connections on pipes, tanks, and other vessels while they are still in service.

Cost Considerations of Hot Taps

Hot taps provide a convenient and cost-effective way to expand water or steam flow in a system. Typically, hot taps are used to connect a new branch line into an existing pipe or system. The cost considerations of hot tapping can vary depending on the size and complexity of the job. The most important cost factors include permits, labor costs, and materials.

Permits are necessary for any hot tap job, and it is important to factor in the cost of acquiring the necessary permit before beginning the project. Labor costs for a hot tap job can also be expensive, as the process is complex and requires experienced technicians. Additionally, the materials needed for a hot tap job are often costly, so it’s important to factor these costs into the budget.

Fortunately, hot tapping can save the expense of replacing an entire pipe or system. The process is much faster and more cost-effective than installing a new pipe or system, so it is a great option for those looking to expand their water or steam flow on a budget. For more information on hot taps, their cost considerations, and how they can benefit your project, contact an experienced professional today.

Final Thoughts on Hot Taps

Hot taps are an invaluable tool for a variety of plumbing and maintenance jobs. Because of their versatility, they can be used to perform a wide range of tasks, including cutting into existing pipes, draining systems, and making new connections. However, hot taps require careful preparation and expertise to ensure that they are used safely and correctly. To use a hot tap, you must have the right equipment, the right tools, and the right knowledge. This includes having the right size and type of drill bit for the job, the right hot tap machine, and the right safety gear. Additionally, you should have a thorough understanding of the process and know how to use the equipment correctly. With all of these components in place, you can be sure that you will be able to complete your hot tap project safely and efficiently.

FAQs About the What Do You Need For A Hot Tap?

1. What type of tools are required for a hot tap?

-A hot tap requires a specialized set of tools including a hot tap machine, a drill, an adapter, a tapping valve, and a tapping sleeve.

2. How long does a hot tap take to complete?

-The length of time required to complete a hot tap can vary depending on the size of the pipe and the complexity of the task, but typically takes anywhere from two to four hours.

3. Are there any safety precautions that should be taken when performing a hot tap?

-Yes, it is important to follow all safety guidelines when performing a hot tap. This includes wearing protective gear such as safety glasses and gloves, having proper ventilation, and ensuring that all tools and equipment are properly maintained and in good working condition.

Conclusion

In conclusion, hot tapping is a great way to tap into existing pipelines and add new lines without having to shut down operations. It requires specific tools and equipment to be successful, such as a hot tap machine, drill bits, saws, and safety equipment. Additionally, the right procedures and safety protocols must be followed in order to ensure the process is done properly. With these elements in place, hot tapping is an effective way to make connections in existing pipelines.